The end of a single wire rope is bent back along the wire rope to form the eye. Strands are hand-tucked into the body of the rope in what is called a tapered and concealed splice. The splice makes a sling that can be easily pulled through narrow spaces because there are no rough ends to snag on loads. Slings with wire rope bodies larger than 1-1/2" diameter are made only with burnt end spices in which the ends of strands are left exposed and then cut off with a torch. These ends may also be cut shorter and served for smoothness. Either method has the same rated capacity, size for size. WARNING: Hand-spliced slings should not be used in lifts where the sling may rotate and cause the wire rope to unlay.

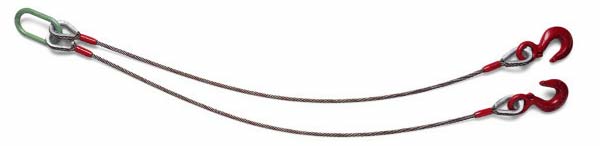

Two and multi-legged bridles. Multi-legged bridles - with two, three or four straight legs - are offered with plain eyes, thinble eyes, open sockets, closed sockets, shackles or turnbuckles. Rated capacities shown for multi-leg slings are for slings that have all legs the same length and all legs are equally sharing the load being lifted. For other conditions, contact our Fabricated Products Engineering Department.

|