|

|

|

|

|

Piggy Back Rope Clips

|

|

|

An easy way to serue the dead end of a wire rope on a wedge socket.

||

|

Dual saddle design secures the dead end of a wire rope on a

wedge socket and procides the following benefits:

- Attaches quickly and easily.

- Eliminates need for short rope piece or loop on dead end.

- Properly secured dead end reduces possibility of snag/foul

and shear off at wedge socket.

- Available in 3/8" to 1 1/2" sizes.

- Dropped forge saddles.

- Application approved by OSHA.

- Hot dip galvanized, plus orange painted U-bolts.

|

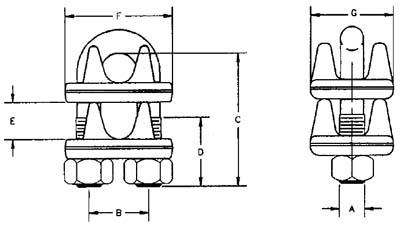

Piggy Back wire rope clip specifications

|

Size (in.) |

Dimensions (inches)

|

Weight each (lbs.) |

Min tail (in.) |

Torque*

(ft -lbs.) |

A |

B |

C |

D |

E |

F |

G |

| 3/8 |

7/16-14UNC |

1.00 |

2.38 |

1.00 |

1.53 |

1.94 |

1.62 |

1.8 |

6 |

145 |

| 7/16 |

1/2-13UNC |

1.19 |

2.62 |

1.00 |

1.66 |

2.31 |

1.78 |

1.3 |

6 |

165 |

| 1/2 |

1/2-13UNC |

1.19 |

2.62 |

1.00 |

1.72 |

2.31 |

1.91 |

1.4 |

6 |

165 |

| 9/16 |

9/16-12UNC |

1.31 |

3.19 |

1.25 |

1.77 |

2.50 |

1.97 |

1.7 |

6 |

195 |

| 5/8 |

9/16-12UNC |

1.31 |

3.19 |

1.25 |

1.81 |

2.50 |

2.00 |

1.7 |

6 |

195 |

| 3/4 |

5/8-11UNC |

1.50 |

3.50 |

1.50 |

1.91 |

2.81 |

2.34 |

2.5 |

6 |

130 |

| 7/8 |

3/4-10UNC |

1.75 |

3.88 |

2.00 |

1.07 |

3.16 |

2.44 |

3.6 |

6 |

225 |

| 1 |

3/4-10UNC |

1.88 |

4.25 |

2.00 |

1.22 |

3.47 |

2.62 |

3.9 |

6 |

225 |

| 11/8 |

3/4-10UNC |

2.00 |

4.50 |

2.00 |

1.31 |

3.59 |

2.81 |

4.9 |

63/4 |

225 |

| 11/4 |

7/8-9UNC |

2.31 |

5.25 |

2.38 |

1.50 |

4.22 |

3.18 |

6.5 |

71/2 |

360 |

| 13/8 |

7/8-9UNC |

2.38 |

5.62 |

2.38 |

1.56 |

4.25 |

3.08 |

7.1 |

81/4 |

360 |

| 11/2 |

7/8-9UNC |

2.59 |

6.00 |

2.38 |

1.75 |

4.47 |

3.41 |

8.2 |

9 |

360 |

|

*The tightening torque values shown are based upon the threads being clean,

dry and free of lubrication.

|

|

NOTE: Rotation resistant rope may require longer tail length.

|

Proper use of PiggyBack Wedge Socket Clips:

- Dead end wire rope tail length should be at least 6 rope diameters, but not less

than 6 inches beyond the wedge socket. Figure 1.

- Apply U-bolt and first saddle on dead end rope and the second saddle on live end

rope. Install nuts. Figures 1 & 2.

- Position the dual saddle clip so that 3 to 4 inches of dead end rope remain

beyond the clip. Figures 1 & 2.

- Tighten nuts evenly. Alternate tightening each nut until reaching the required

torque specified. Figure 2.

- Check that clip does not pinch or clamp the live wire rope. Apply an initial

test load equal to the loads expected in regular use. Be certain rope is secured

properly in the wedge socket prior to anyuse.

- Inspect for proper rope alignment with wedge socket and retighten the nuts to

the specified torque.

|

|

|

|

|

|