|

|

|

|

|

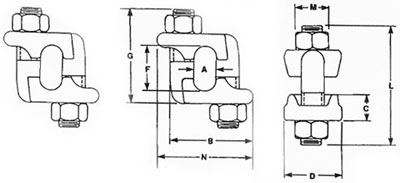

Forged Wire Rope Fist Clip

|  |

|

- Fist Clip wire rope clips meet Federal Specifications FF-C-450, Type III, Class 1, and will provide maximum holding strength when installed and used according to specifications.

- Double grip, double saddle wire rope clips allow full arc wrench swing for quicker installation, retightening or disassembly of nuts.

- Unlike U-bolt type rope clips, Mid-Grip clips cannot be installed incorrectly with the saddle not on the live rope end.

- Forged from special bar quality steel with the sizes clearly marked on the saddles.

- Hot galvanized with galvanized heavy hex nuts. When properly used, fist clips will give terminal efficiency ratings of approximately 80% of the catalog nominal strengths of new wire rope.

|

Size (in.) |

Dimensions (inches) |

Min. no clips |

Rope turnback (in.) |

Torque+ (ft -lbs.) |

Weight per 100 (lbs.) |

| A |

B |

C |

D |

Thd. |

F |

G |

L approx. |

M |

N |

3/16 & 1/4 |

.28 |

1.25 |

.34 |

.94 |

3/8-16 |

.50 |

1.28 |

1.56 |

.69 |

1.28 |

2 |

4 |

30 |

21 |

5/16 |

.34 |

1.38 |

.44 |

1.06 |

3/8-16 |

.63 |

1.47 |

1.81 |

.69 |

1.41 |

2 |

5 |

30 |

27 |

3/8 |

.41 |

1.56 |

.50 |

1.06 |

7/16-14 |

.75 |

1.81 |

2.31 |

.75 |

1.85 |

2 |

5 1/4 |

45 |

45 |

7/16 |

.50 |

1.78 |

.56 |

1.25 |

1/2-13 |

1.00 |

2.19 |

2.75 |

.88 |

2.06 |

2 |

6 1/2 |

65 |

65 |

1/2 |

.50 |

1.78 |

.56 |

1.25 |

1/2-13 |

1.00 |

2.19 |

2.75 |

.88 |

2.06 |

3 |

11 |

65 |

65 |

9/16 |

.66 |

2.25 |

.69 |

1.50 |

5/11 |

1.25 |

2.69 |

3.31 |

1.06 |

2.59 |

3 |

12 3/4 |

130 |

113 |

5/8 |

.66 |

2.25 |

.69 |

1.50 |

5/8-11 |

1.25 |

2.69 |

3.31 |

1.06 |

2.59 |

3 |

13 1/2 |

130 |

113 |

3/4 |

.81 |

2.69 |

.88 |

1.81 |

3/4-10 |

1.50 |

2.94 |

3.44 |

1.25 |

3.06 |

3 |

16 |

225 |

170 |

+ The tightening torque values shown are based upon the threads being clean, dry and free of lubrication.

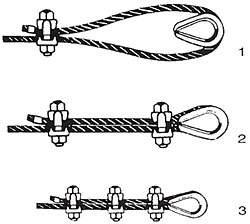

Proper use of Forged Wire Rope Fist Clips:

- Refer to chart above in following these instructions. Turn back specified amounts of rope from thimble or loop. Apply first clip one base width from dead end of rope. Tighten nuts evenly, alternating from one nut to the other until reaching the recommended torque.

- When two clips are required, apply the second clip as near the loop or thimble as possible. Tighten nuts evenly, alternating until reaching the recommended torque. When more than two clips are required, apply the second clip as near the loop or thimble as possible, turn nuts on second clip firmly, but do not tighten. Proceed to step 3.

- When three or more clips are required, space additional clips between first two - take up rope slack - tighten nuts on all clips, alternating from one nut to the other until reaching the recommended torque.

- Apply an initial load equal to loads expected in use. Inspect for proper spacing and retighten the nuts to the recommended torque.

|

|

|

|

|

|